Our SHRED grinders range from small, compact units up to mammoth waste shredders that quickly cut problem solids down to size. Two rows of sharp, steel cutters rotate slowly and with incredibly high-torque to turn large troublesome solids into tiny particles. We can even stack shredders in order to turn very large solids into tiny pieces.

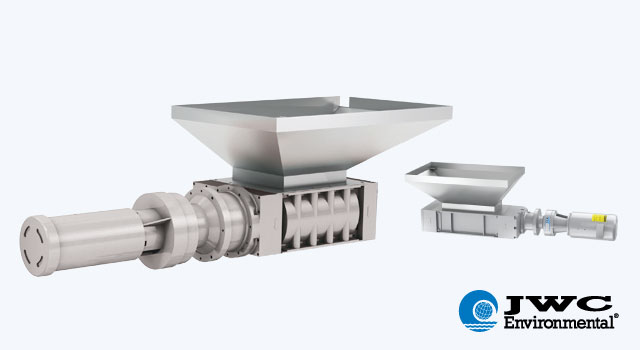

SHRED grinders are typically installed horizontally with a stainless steel hopper on top. Conveyors or augers feed material into the hopper where it then falls into the slow rotation, high-torque central cutter shafts. We custom design and build each shredder and hopper to match your exact specifications.

These ultra-rugged dual-shafted grinders are used in a wide range of industries including petroleum, wastewater, agriculture, food processing, manufacturing, ship food waste, e-waste destruction and more. SHRED grinders offer plenty of cutting power and need only a 3-10 HP motor to get the job done. These incredibly energy efficient motors help you shred more material for less.